Mig Welding Machine

Mig welding machine that are useful in fixings objects or mounting on any suitable surface. These diode & mig welding machines are manufactured using extreme quality of precision and hardened ground p ...

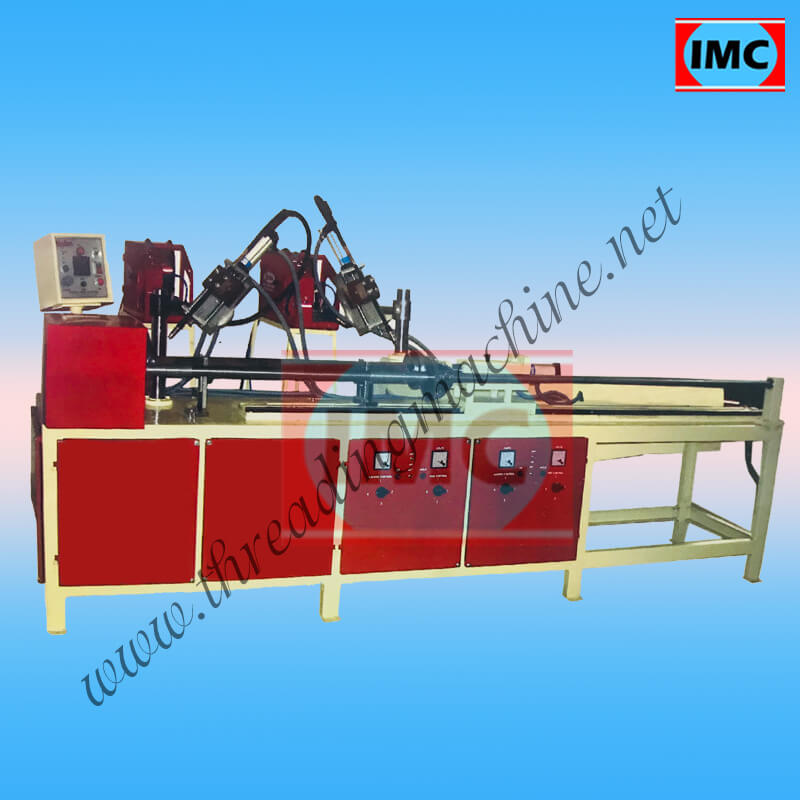

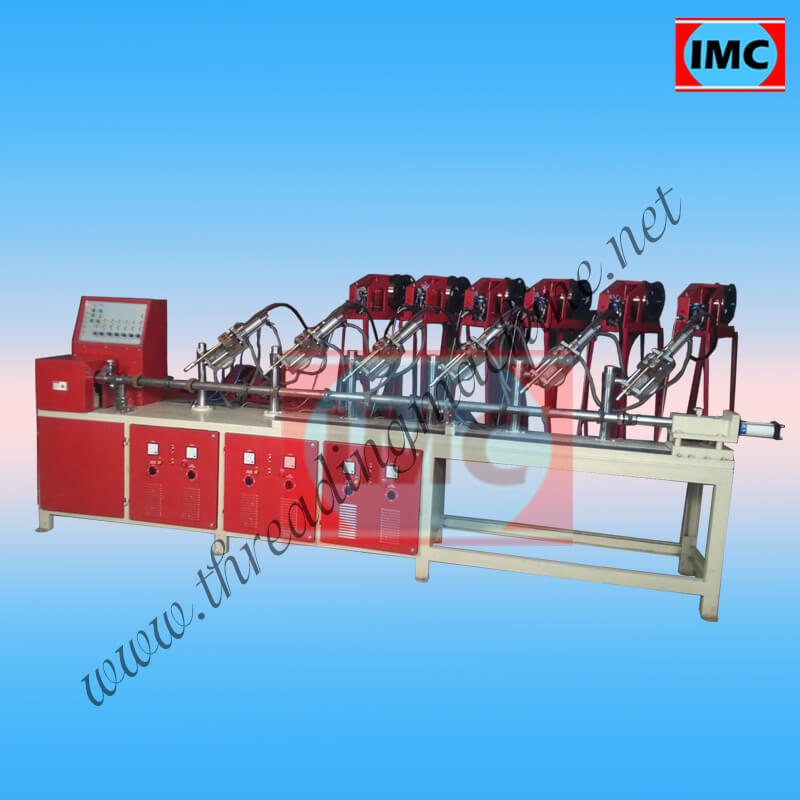

VIEW MOREIntroducing the groundbreaking Base Jack Welding Machine, expertly manufactured and supplied by IMC. As a leading manufacturer and supplier, IMC brings you a machine that revolutionizes base jack welding with its innovative design and exceptional performance.

Automatic Base jack welding machine is used to weld base plate with pipe without making any joint between them, It gives high production and accuracy to product. Base jack welding machine welds solid jacks, Tie rods, Hollow jacks with base plate. Base jack are used with combination of Cuplock welding to make a structure. All the components are used in combination of each other Base jack welding machine, Inner prop welding machine, Outer prop welding machine, Cuplock welding machine, Ringlock welding machine

Designed for efficiency and precision, the Base Jack Welding Machine is a game-changer in the construction industry. It seamlessly welds base jacks, ensuring a strong and reliable connection that withstands the rigors of heavy-duty applications. Say goodbye to traditional methods and experience the efficiency and reliability of automated base jack welding.

Key Specifications:

Welding Capacity: The Base Jack Welding Machine boasts an impressive welding capacity, accommodating a wide range of base jack sizes. From standard sizes to custom specifications, this machine handles them all with remarkable ease and precision.

Welding Technique: This machine utilizes advanced welding techniques, such as MIG (Metal Inert Gas) welding, ensuring strong and durable welds. The precise control of welding parameters guarantees consistent and high-quality welds every time.

Welding Speed: Equipped with a high-performance welding system, the machine delivers rapid welding speeds, optimizing productivity and reducing welding cycle times. It enables you to meet demanding project deadlines without compromising on weld quality.

Adjustable Features: This Machine offers adjustable features to accommodate different base jack configurations. It allows for easy adjustments of welding angles, torch position, and welding parameters, ensuring versatility and adaptability to varying welding requirements.

Control Panel: The machine features an intuitive control panel that provides user-friendly operation and easy access to welding parameters. Operators can easily set and adjust welding parameters, monitor the welding process, and ensure precise control over the welding operation.

Safety Features: IMC prioritizes operator safety. This Machine is designed with comprehensive safety features, including emergency stop buttons, protective enclosures, and safety sensors that ensure safe operation and protect the operator from potential hazards.

IMC's commitment to quality and reliability is evident in every aspect of the Base Jack Welding Machine. Each component is meticulously crafted from high-quality materials and undergoes rigorous testing to meet international standards. This machine is built to withstand heavy-duty use and provides exceptional durability and long-lasting performance.

As a trusted manufacturer and supplier, IMC has earned a reputation for delivering top-of-the-line machinery. IMC's Base Jack Welding Machines have garnered acclaim for their robust construction, advanced technology, and unmatched customer satisfaction. By choosing IMC as your supplier, you gain access to comprehensive support from a dedicated team of experts.

From installation and training to ongoing maintenance and technical assistance, IMC ensures that you receive the utmost support throughout the lifecycle of your machine. With IMC as your partner, you can optimize your base jack welding processes, enhance productivity, and gain a competitive edge in the construction industry.

Experience the efficiency and precision of the Base Jack Welding Machine from IMC, and witness a new era of base jack welding. Trust IMC's expertise and commitment to innovation to elevate your welding capabilities. Choose IMC, your trusted partner in the industry, and unlock limitless possibilities for your business.

| Electric Supply | Single Phase 220 + - 10 % Volts Frequency HZ 50/60 | ||

| Speed | 2 to 10 RPM | ||

| Motor Drive | 75 C | ||

| Motor Type | DC | ||

| Torch Clamping | PNEUMATIC | ||

| Length Adjustment | Up to 1000 mm | ||

| Dimension | L x W x H 5.4x2.5x4.7 (Foot) |

Mig welding machine that are useful in fixings objects or mounting on any suitable surface. These diode & mig welding machines are manufactured using extreme quality of precision and hardened ground p ...

VIEW MORE

Industrial Machinery Corporation is proud to present the Outer Prop Welding Machine, a specialized solution designed for welding outer props used in construction and support structures. With advanced ...

VIEW MORE

Automatic Inner prop welding machine is used to weld base plate with pipe without making any joint between them, It gives high production and accuracy to product. Inner prop is used with combination ...

VIEW MORE

Horizontal ledger welding machine is designed to weld ledger blades together at the same time, machine hold and weld the blades proportional to each other. This unit is pneumatically operated for ...

VIEW MORE

Searching for a reliable and high-quality Cups and Lock Pins Tagging Machine? Look no further than Industrial Machinery Corporation (IMC), a trusted manufacturer, exporter, and supplier of top-of-the ...

VIEW MORE

Our Vertical Cup Lock Welding Machine is designed with precision and innovation, offering unparalleled performance and efficiency in the welding of cup lock systems. This machine streamlines the weldi ...

VIEW MORE

A Scaffolding Pipe Punching Machine, also known as a Hole Making Machine, is a piece of equipment designed to punch holes into scaffolding pipes or tubes. Scaffolding is a temporary structure used in ...

VIEW MORE

Introducing our cutting-edge Automatic Scaffolding Cup Sleeve Nut Handle & G Pin Making Machine, a technological marvel designed to revolutionize your manufacturing processes. Crafted with precision e ...

VIEW MORE

Introducing our state-of-the-art Scaffolding Prop Nut Cup Handle Welding Machine – a game-changer in the realm of scaffolding manufacturing. Engineered for efficiency and precision, this machine is ...

VIEW MORE

Introducing our cutting-edge Scaffolding Prop Welding Machine Double-Sided – a groundbreaking solution designed to redefine precision and efficiency in scaffolding manufacturing. This advanced machi ...

VIEW MORE