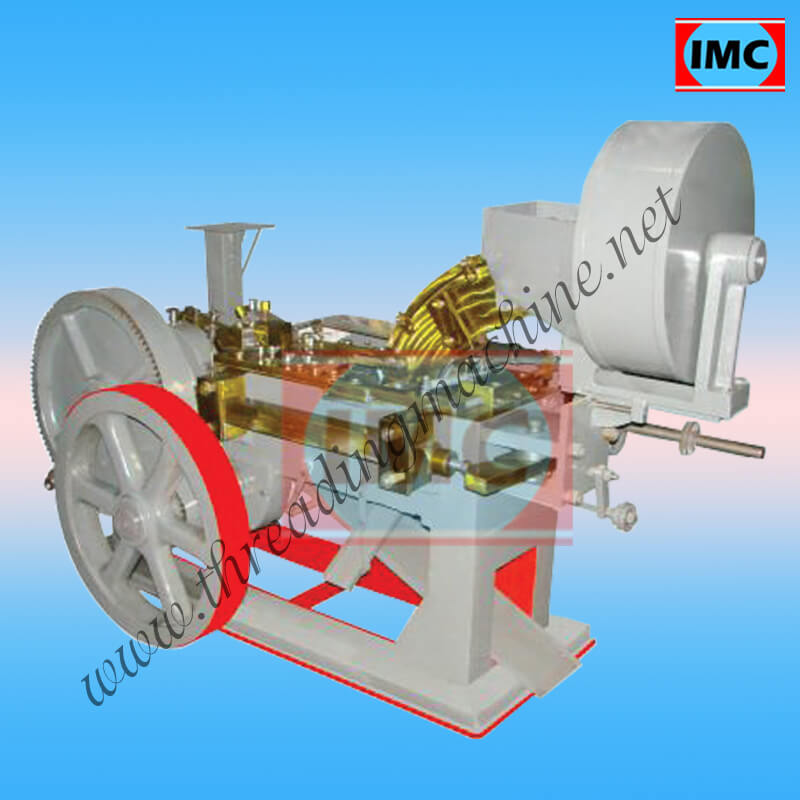

Introducing the extraordinary Automatic Cold Thread Rolling Machine, proudly manufactured and supplied by IMC since 2002. With decades of experience and a relentless commitment to excellence, IMC has solidified its position as a leading manufacturer and supplier of this cutting-edge machine.

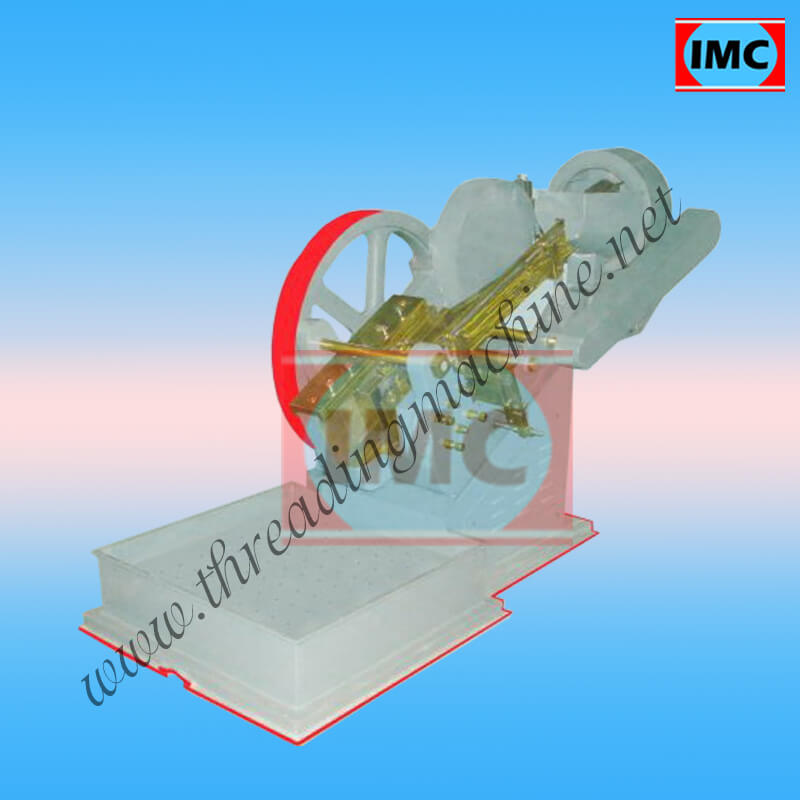

Designed to revolutionize thread rolling operations, this machine combines precision engineering with advanced technology, delivering unparalleled performance and efficiency. Whether you require precise threads on bolts, screws, or other fasteners, the Automatic Cold Thread Rolling Machine ensures flawless results with every operation.

Equipped with state-of-the-art features, this machine maximizes productivity and minimizes downtime. Its high-speed operation and rapid tool change capabilities enable seamless transitions between different thread specifications, allowing you to meet demanding production requirements effortlessly. With IMC's machine, you'll experience increased throughput and enhanced manufacturing efficiency.

Versatility is a cornerstone of the Automatic Cold Thread Rolling Machine. It accommodates a wide range of thread sizes, thread pitches, and materials, giving you the freedom to produce a diverse array of products. From standard threads to specialized designs, this machine handles them all with remarkable precision and consistency.

IMC prioritizes safety without compromising on performance. The Automatic Cold Thread Rolling Machine is designed with comprehensive safety features, ensuring a secure working environment for your operators. Emergency stop mechanisms, protective guards, and advanced sensors work in tandem to safeguard your team while maintaining uninterrupted operation.

Quality is at the heart of IMC's manufacturing process. Every component of the Automatic Cold Thread Rolling Machine undergoes rigorous testing and quality control measures, ensuring exceptional reliability and durability. IMC's unwavering commitment to excellence guarantees that your machine will deliver consistent and superior performance for years to come.

Since 2002, IMC has been a trusted partner for businesses seeking top-of-the-line thread rolling solutions. Our machines have earned a reputation for their robust construction, advanced technology, and outstanding customer satisfaction. When you choose IMC as your supplier, you gain access to a wealth of expertise and unparalleled support.

IMC's dedicated team of professionals provides comprehensive assistance throughout the entire lifecycle of your machine. From initial installation and training to ongoing maintenance and technical support, IMC is committed to your success. With IMC by your side, you can optimize your thread rolling operations and stay ahead in today's competitive market.

Experience the power and precision of the Automatic Cold Thread Rolling Machine from IMC, and elevate your manufacturing capabilities to new heights. With IMC's proven track record of excellence and commitment to innovation, you can trust that your thread rolling processes are in capable hands. Choose IMC, your trusted partner since 2002, and unlock limitless possibilities for your business

.

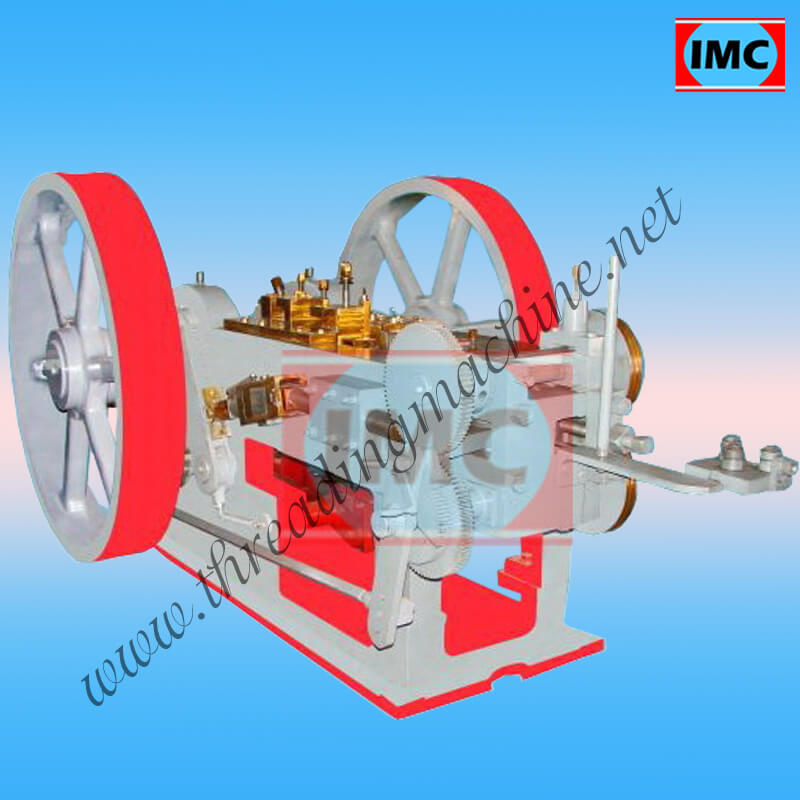

Specifications:

| Model No. | FDTRM-1 | FDTRM-2 | FDTRM-3 | FDTRM-4 | FDTRM-5 | FDTRM-6 | FDTRM-7 |

| Min. Max. Dia Can Be Rolled | 1/16"x1/4" | 1/8"x3/8" | 1/8"x1/2" | 1/4"x5/8" | 1/4"x3/4" | 1/4"x7/8" | 3/8"x1" |

| Max. Length of Thread | 2" | 2.1/2" | 3" | 3" | 4" | 4" | 4" |

| Dimension of Fixed Dia | 3"x2"x1" | 5"x2.1/2"x1" | 5"x3"x1" | 6"x3"x1" | 6"x4"x1" | 7"x4"x1" | 8"x4"x1.1/2" |

| Dimension of Moving Dia | 4"x2"x1" | 6"x2.1/2"x1" | 6"x3"x1" | 7"x3"x1" | 7"x4"x1" | 8"x4"x1" | 9"x4"x1.1/2" |

| Production in Pieces Per Minute | 80 | 60 | 60 | 50 | 30 | 30 | 20 |

| Power Required in H.P. | 2 | 3 | 5 | 7.5 | 10 | 15 | 20 |