Hydraulic Surface Grinder Machine

Introducing our cutting-edge Hydraulic Surface Grinder Machine, a pinnacle of excellence in grinding technology. Engineered with utmost precision and advanced features, this machine is designed to de ...

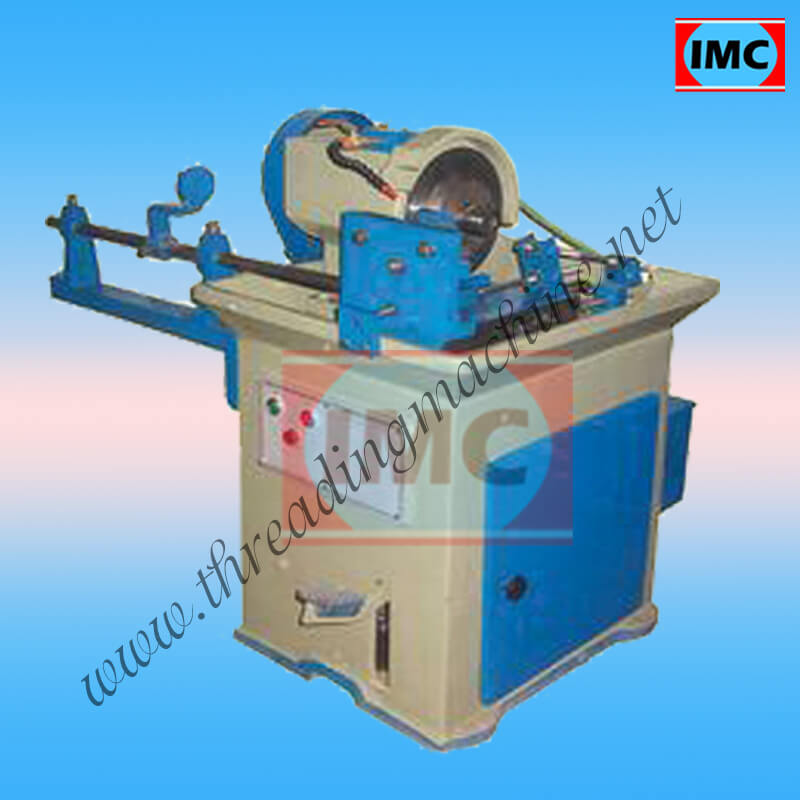

VIEW MOREIMC (Industrial Machinery Corporation) is a well-known manufacturer and supplier of various industrial machines, including pipe and rod polishing machines. IMC offers a range of polishing machines designed to cater to the specific needs of different industries.

A pipe and rod polishing machine is a specialized tool used to polish and finish the surface of pipes and rods. It is commonly employed in various industries such as manufacturing, construction, and metalworking. The machine utilizes abrasive materials and rotating polishing heads to achieve a smooth and polished surface on pipes and rods.

Here are some key features and functions typically found in pipe and rod polishing machines:

Polishing Heads: These machines consist of multiple polishing heads or wheels that rotate at high speeds. The heads are usually adjustable, allowing for flexibility in polishing different diameters and lengths of pipes and rods.

Abrasive Belts or Buffing Wheels: Pipe and rod polishing machines employ abrasive belts or buffing wheels to remove surface imperfections and achieve a desired level of smoothness. The type of abrasive material used can vary based on the specific requirements and the type of metal being polished.

Variable Speed Control: The machines often come with adjustable speed settings, allowing operators to control the polishing process based on the material being polished and the desired finish. Different speeds may be required for various stages of the polishing process.

Feeding System: Pipe and rod polishing machines may feature a feeding system that automatically moves the pipes or rods through the polishing heads. This system ensures consistent and even polishing across the entire length of the workpiece.

Coolant System: Some machines incorporate a coolant system to prevent overheating during the polishing process. Coolant helps maintain the temperature and prolongs the life of the polishing heads and abrasive materials.

Dust Collection: Polishing can generate a significant amount of dust and debris. To maintain a clean working environment, some machines include a dust collection system that captures and collects the particles generated during polishing.

Safety Features: Pipe and rod polishing machines often come equipped with safety features such as emergency stop buttons, safety guards, and protective shields to prevent accidents and ensure operator safety.

It's important to note that specific features and functionalities can vary depending on the manufacturer and model of the pipe and rod polishing machine. Therefore, it's always recommended to refer to the machine's user manual for detailed instructions on its operation and maintenance.

Pipe and Rod Polishing Machine Features:

| Automatic Grade | Semi-automatic, Fully-automatic |

| Power (HP) | 3 H.P., 1440 RPM |

| Specifications : | |

| Dia in Wire/Rod | 3 to 25 |

| Dia in Pipe | 6 to 50 |

| Abrasive Belt | 50 x 2000 |

| Power of Motor | 3 H.P., 1440 RPM |

| Approx. Weight in Kg. | 400/500 Kg. |

| Floor space required | 27"x 20" |

Introducing our cutting-edge Hydraulic Surface Grinder Machine, a pinnacle of excellence in grinding technology. Engineered with utmost precision and advanced features, this machine is designed to de ...

VIEW MORE

Looking for a reliable and high-quality Buffing Machine? Look no further than Industrial Machinery Corporation (IMC), a renowned manufacturer, exporter, and supplier of top-notch buffing machines. Wi ...

VIEW MORE

The Tap and Tool Grinder Machine is used to re-sharpen the taps and tools. Taps, like all other cutting tools, become dull through use. Dull taps can produce either oversize or undersized holes. They ...

VIEW MORE

Pipe cutting machine removes material from pipe or tube to create a desired profile. Typical profiles include straight cuts, mitres, saddles and midsection holes. These complex cuts are usually requi ...

VIEW MORE

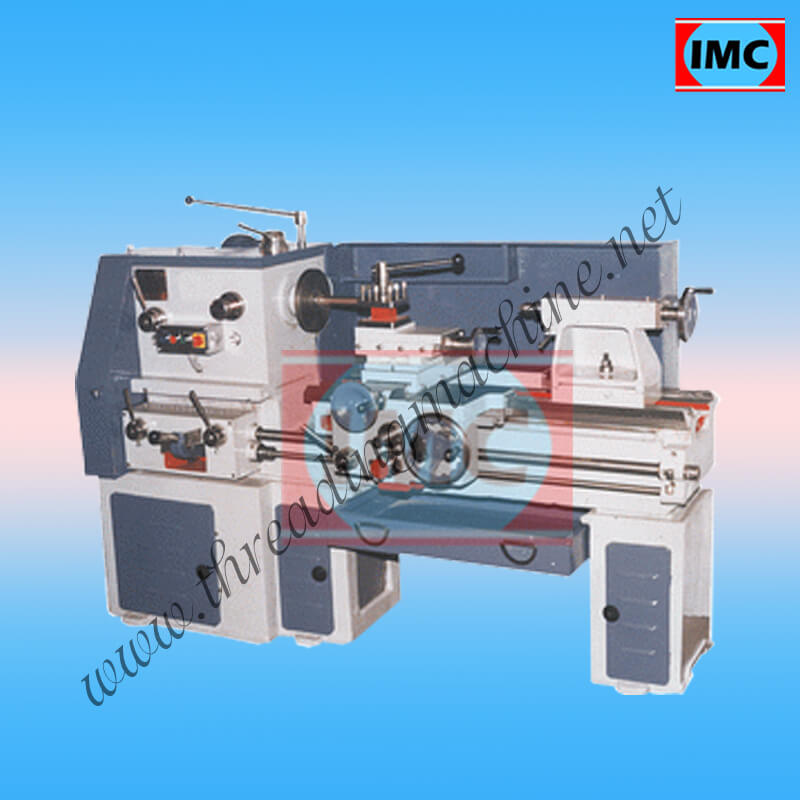

While there are a number of lathe machines available in the market today, there are some that are specialized and can be used only for specific purposes. These are used for specific purposes ...

VIEW MORE

Pipe End Facing Machine is used to Chamfering and Deburring of the Pipes before Threading operation and Galvanizing. The Job is chamfered from the External, Internal and Front Face Three different too ...

VIEW MORE