PVC pipe threading machines are specifically designed for cutting threads on PVC (polyvinyl chloride) pipes. These machines are used in various industries, including plumbing, irrigation, and construction, where threaded PVC pipes are required for proper connections and installations.

Here are some key features and considerations when it comes to PVC pipe threading machines:

Compatibility: PVC pipe threading machines are designed to work specifically with PVC pipes. The machine should be compatible with the diameter and wall thickness of the PVC pipes you intend to thread.

Threading Mechanism: These machines typically use cutting dies or chasers to create threads on the PVC pipes. The threading mechanism may involve rotating dies or chasers that engage with the PVC pipe to cut the threads.

Size Range: PVC pipe threading machines are available in different models to accommodate various pipe sizes. Ensure that the machine you choose can handle the specific pipe diameters you will be working with.

Thread Types: PVC pipe threading machines can cut various types of threads, including parallel and tapered threads. The specific thread standards supported by the machine may vary, so it's important to confirm compatibility with the required thread type.

Power Source: PVC pipe threading machines can be powered by electricity or may have manual operation options. Electrically powered machines are generally more efficient and offer faster threading speeds.

Clamping Mechanism: These machines may feature a clamping mechanism to secure the PVC pipe during the threading process. The clamping mechanism ensures stability and prevents movement or rotation of the pipe.

Durability and Safety: Look for a PVC pipe threading machine that is constructed with durable materials and built to withstand the demands of threading PVC pipes. Safety features such as protective guards and emergency stop buttons are also important for safe operation.

When considering a PVC pipe threading machine, it is recommended to consult the manufacturer's specifications and guidelines to ensure that the machine is suitable for your specific PVC pipe threading requirements. Additionally, proper training and adherence to safety guidelines are essential when operating these machines to prevent accidents and achieve optimal threading results.

Range of IMC PVC Pipe Threading Machines and Die Heads.

1/4" to 1" do/-

3/8" to 1.1/2" do/-

1/2" to 2.1/2" do/-

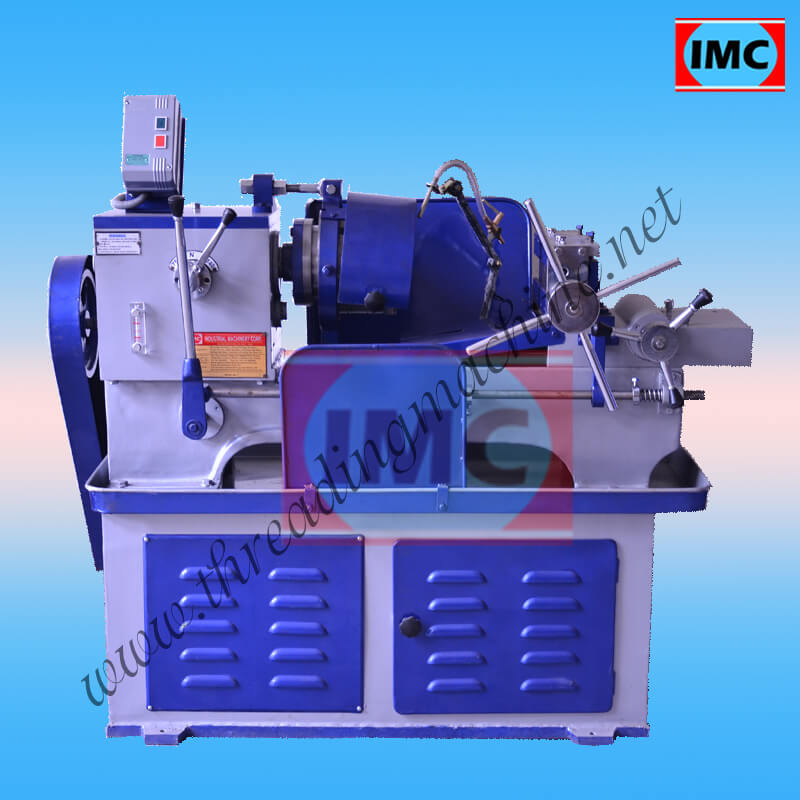

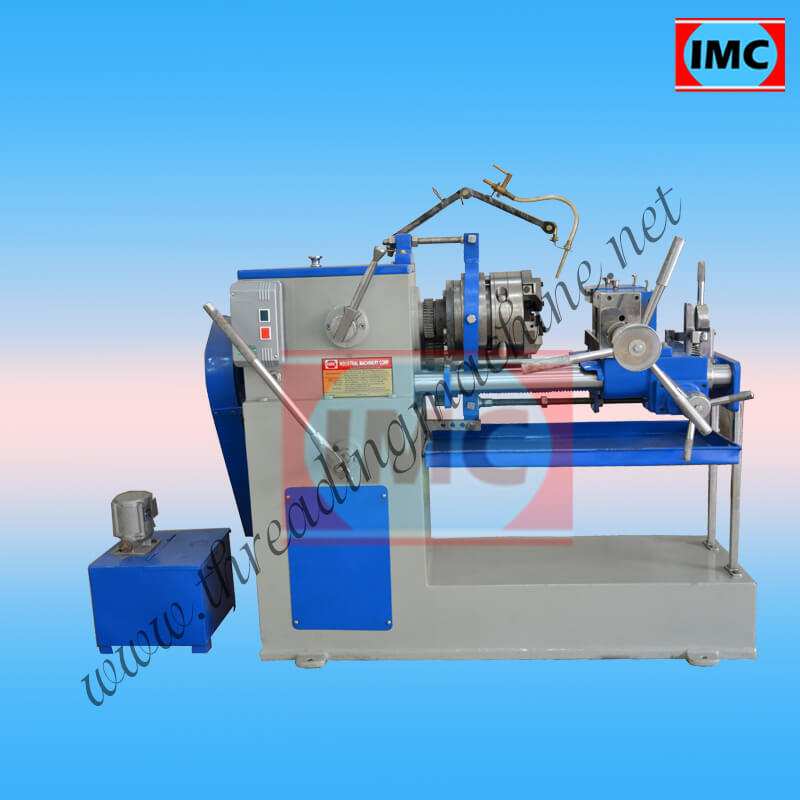

PVC Pipe Threading Machine

| Model | 3/8" to 2" (10MM to 50MM)

| 1/2" to 2.1/2" (12MM to 65MM)

| 1" to 4" (25MM to 100MM)

| 2.½" to 6" (65MM to 150MM)

| 4" to 8" (100MM to 200MM)

| 8" to 10" (200MM to 250MM)

|

| Saddle Movement | 10"- 12" | 16" | 10“ - 12" | 8" | 8" | 8" |

| Spindle Speed Range | 127-180 | 60-90-120 | 40-75-115 | 25-50 | 25-50 | 10-20-30 |

| Number of Spindle Speed | 2 | 3 | 3 | 2 | 2 | 3 |

| Threading Capacity | 3/8" to 2" | 1/2" to 2.1/2"

| 1 to 4" | 2.1/2" to 6" | 4" to 8" | 8" to 10" |

| Production per Hour | 100-120 | 70-90 | 35-40 | 20-25 | 15-20 | 15-20 |

| H.P. Required | 3 H.P. | 7.5 H.P. | 12.5 H.P. 960 | 15 H.P. 960 | 20 H.P. 960 | 30 H.P. 960 |

| Lead Screw | Provided | Provided | Provided | Provided | Provided | Provided |

| Weight (KG) Approx. | 550 | 990 | 1600 | 1900 | 2500

| 5000

|