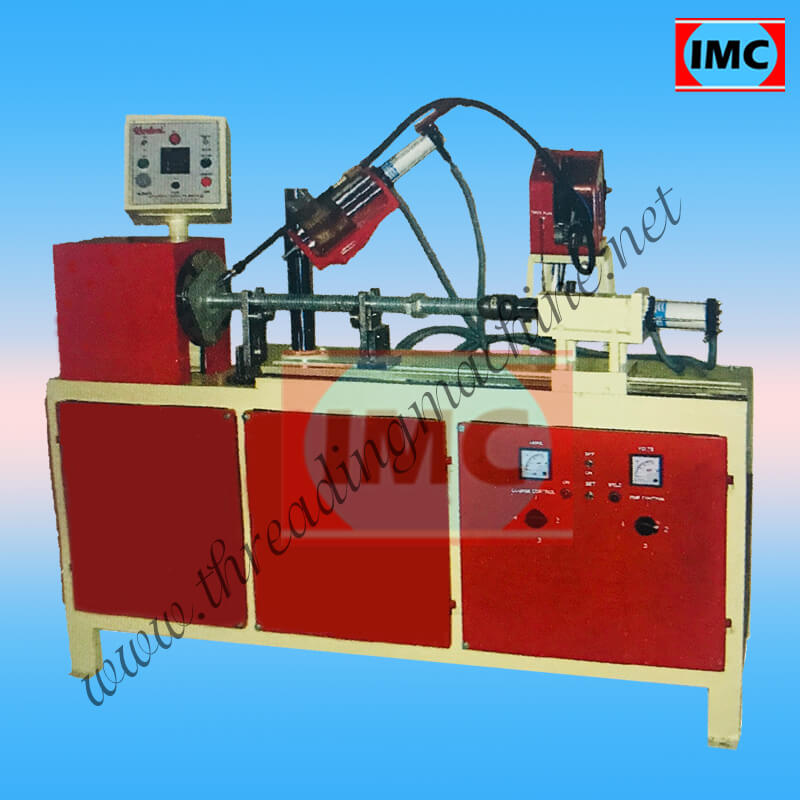

Mig Welding Machine

Mig welding machine that are useful in fixings objects or mounting on any suitable surface. These diode & mig welding machines are manufactured using extreme quality of precision and hardened ground p ...

VIEW MOREA Scaffolding Pipe Punching Machine, also known as a Hole Making Machine, is a piece of equipment designed to punch holes into scaffolding pipes or tubes. Scaffolding is a temporary structure used in construction to support workers and materials during the building or maintenance of structures. The holes punched in scaffolding pipes are used for various purposes, including connecting different components of the scaffolding system, facilitating assembly, and ensuring stability.

A Scaffolding Pipe Punching Machine, also known as a Hole Making Machine, is a piece of equipment designed to punch holes into scaffolding pipes or tubes. Scaffolding is a temporary structure used in construction to support workers and materials during the building or maintenance of structures. The holes punched in scaffolding pipes are used for various purposes, including connecting different components of the scaffolding system, facilitating assembly, and ensuring stability.

Key features of a Scaffolding Pipe Punching Machine include:

Punching Mechanism: The machine is equipped with a mechanism that punches holes into the scaffolding pipes. This mechanism may involve hydraulic, pneumatic, or mechanical components.

Adjustable Hole Size and Spacing: The machine typically allows for the adjustment of hole size and spacing, accommodating different specifications and requirements based on the type of scaffolding being used.

Control Panel: Similar to other industrial machines, a control panel is often present to set parameters such as hole diameter, spacing, and other relevant factors. This can contribute to the precision and repeatability of the hole-punching process.

Feeding Mechanism: Scaffolding pipes need to be fed into the machine for the hole-punching process. The feeding mechanism ensures a continuous and controlled operation.

Safety Features: Safety is a critical consideration in the design of industrial machines. Emergency stop buttons, safety guards, and other features may be incorporated to protect operators.

Material Compatibility: The machine should be designed to work with the types of materials commonly used in scaffolding, such as steel or aluminum pipes.

The hole-making process is essential in scaffolding construction as it allows for the assembly of different components, connection points, and the attachment of accessories. The use of a dedicated machine for this purpose helps ensure efficiency, accuracy, and consistency in the hole-punching process, contributing to the overall quality and safety of the scaffolding structure.

As with any industrial machine, operators should follow safety guidelines and procedures to prevent accidents and ensure the proper functioning of the equipment.

Mig welding machine that are useful in fixings objects or mounting on any suitable surface. These diode & mig welding machines are manufactured using extreme quality of precision and hardened ground p ...

VIEW MORE

Industrial Machinery Corporation is proud to present the Outer Prop Welding Machine, a specialized solution designed for welding outer props used in construction and support structures. With advanced ...

VIEW MORE

Automatic Inner prop welding machine is used to weld base plate with pipe without making any joint between them, It gives high production and accuracy to product. Inner prop is used with combination ...

VIEW MORE

Introducing the groundbreaking Base Jack Welding Machine, expertly manufactured and supplied by IMC. As a leading manufacturer and supplier, IMC brings you a machine that revolutionizes base jack wel ...

VIEW MORE

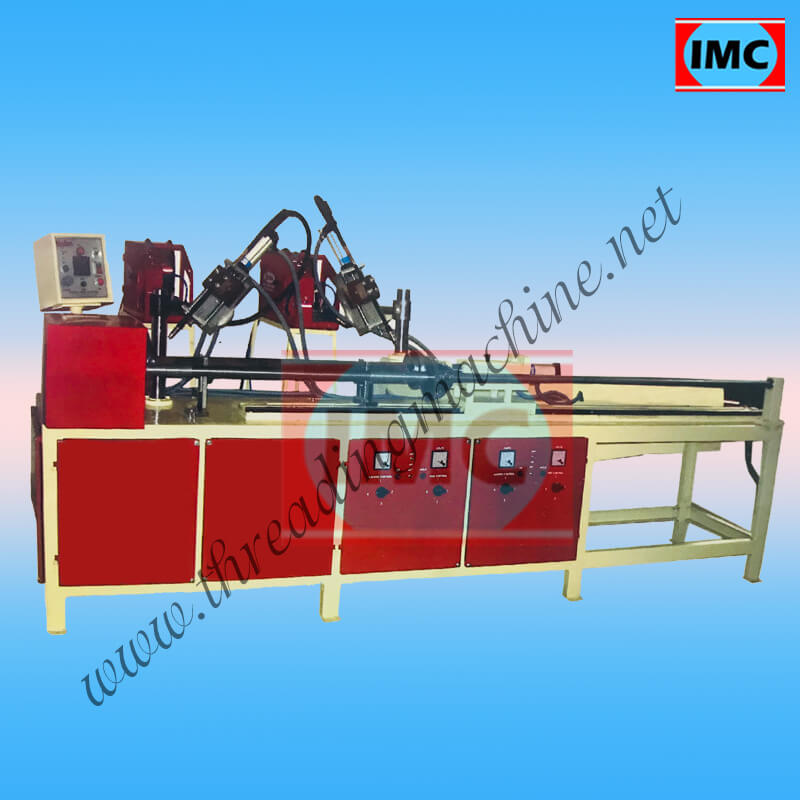

Horizontal ledger welding machine is designed to weld ledger blades together at the same time, machine hold and weld the blades proportional to each other. This unit is pneumatically operated for ...

VIEW MORE

Searching for a reliable and high-quality Cups and Lock Pins Tagging Machine? Look no further than Industrial Machinery Corporation (IMC), a trusted manufacturer, exporter, and supplier of top-of-the ...

VIEW MORE

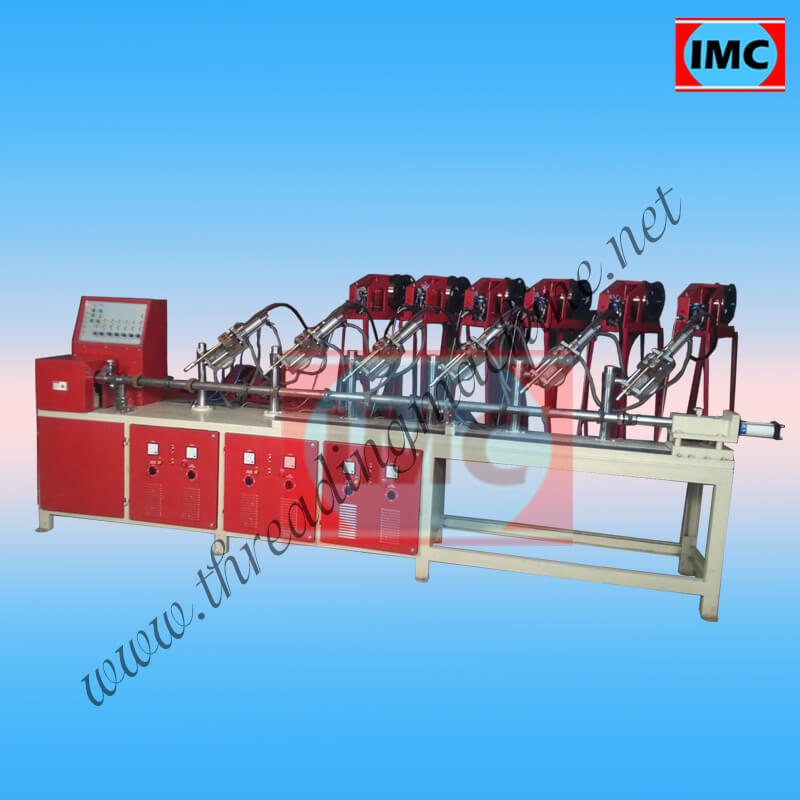

Our Vertical Cup Lock Welding Machine is designed with precision and innovation, offering unparalleled performance and efficiency in the welding of cup lock systems. This machine streamlines the weldi ...

VIEW MORE

Introducing our cutting-edge Automatic Scaffolding Cup Sleeve Nut Handle & G Pin Making Machine, a technological marvel designed to revolutionize your manufacturing processes. Crafted with precision e ...

VIEW MORE

Introducing our state-of-the-art Scaffolding Prop Nut Cup Handle Welding Machine – a game-changer in the realm of scaffolding manufacturing. Engineered for efficiency and precision, this machine is ...

VIEW MORE

Introducing our cutting-edge Scaffolding Prop Welding Machine Double-Sided – a groundbreaking solution designed to redefine precision and efficiency in scaffolding manufacturing. This advanced machi ...

VIEW MORE