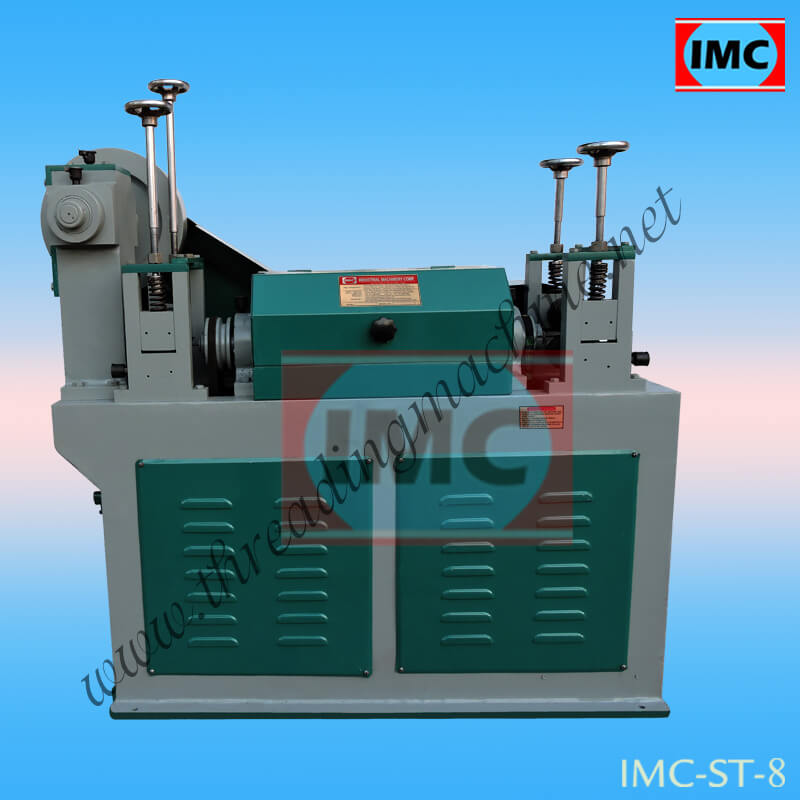

Wire Straightening And Cutting Machine

The main characteristics of this Wire Straightening Cutting Machine are a modern design, low maintenance, and high throughput. These machines are available in various capacities that depend upon the thickness, weight, speed, and length of the wire.

Tags

Wire Straightening And Cutting Machine, Industrial machinery, Industrial machinery Manufacturer in India, Machinery Exporter in India, India, Ludhiana Punjab India, wire straightening and cutting machine in india, wire straightening and cutting machine price in india, wire straightening machine priceAvailable Options

Specifications

A wire straightening and cutting machine is a type of industrial equipment used for straightening and cutting wires to specific lengths. It is commonly used in industries such as construction, manufacturing, and electrical wiring, where wires need to be prepared for various applications.

The machine consists of a feeding system that guides the wire through a series of rollers or straightening blocks. These rollers or blocks help to remove any bends, twists, or kinks in the wire, ensuring it is perfectly straight. After the straightening process, the machine automatically cuts the wire into predetermined lengths using a cutting mechanism such as blades or shears.

Wire straightening and cutting machines offer several advantages over manual methods of wire preparation. They are highly efficient and can handle large volumes of wire at a rapid pace, significantly increasing productivity. The machines also provide consistent and accurate results, ensuring that each wire is straightened and cut to the desired length with precision.

Different wire straightening and cutting machines are available to accommodate various wire diameters and lengths. Some machines can handle thin wires, while others are designed for thicker and heavier wires. The cutting length can often be adjusted to meet specific requirements.

Overall, wire straightening and cutting machines are essential tools for industries that frequently work with wires. They streamline the wire preparation process, saving time and effort while improving the quality and consistency of the final product.

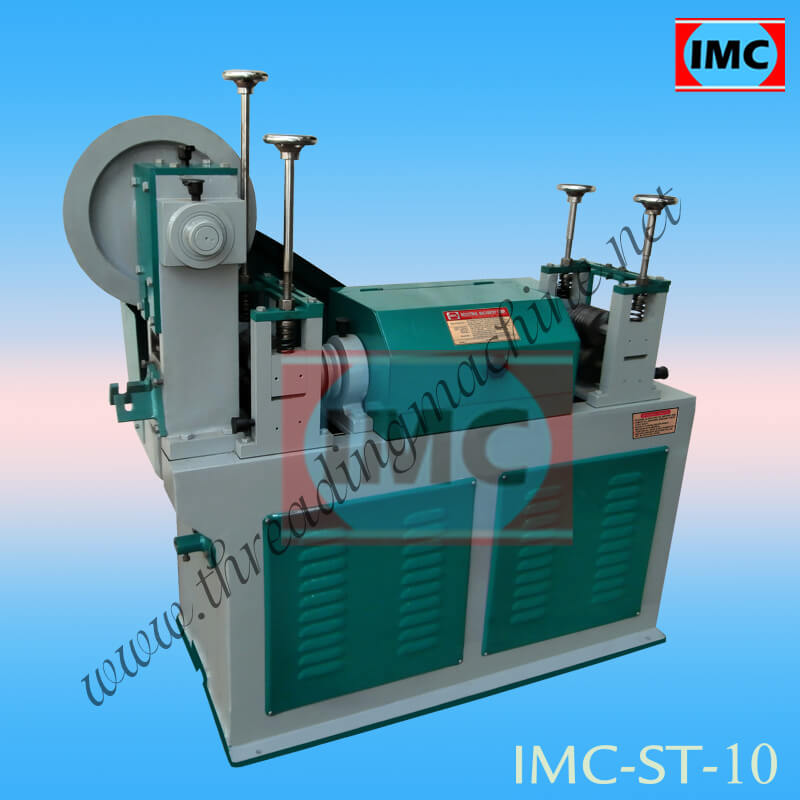

| Specifications : | IMC-ST-7 | IMC-ST-8 | IMC-ST-10 | IMC-ST-12 | IMC-ST-13 |

| In Thickness of wire | 2 to 7mm | 3 to 8mm | 4 to 10mm | 4 to 12mm | 3 to 13mm |

| In Length of wire to be cut automatically | As per Requirement | As per Requirement | As per Requirement | As per Requirement | As per Requirement |

| Feeding capacity per min. | 70' feet | 70' feet | 70' feet | 60' feet | 60' feet |

| Power of motor H.P. | 3 H.P. | 5 H.P. | 5 H.P. | 10 H.P. | 10 H.P. |

| Required R.P.M. | 1440 | 1440 | 1440 | 1440 | 1440 |

| Approx. Weight in Kg. | 410 | 460 | 550 | 1000 | 1200 |

| Floor space required | 42"x18" | 48"x20" | 52"x20" | 60"x22" | 82"x22" |

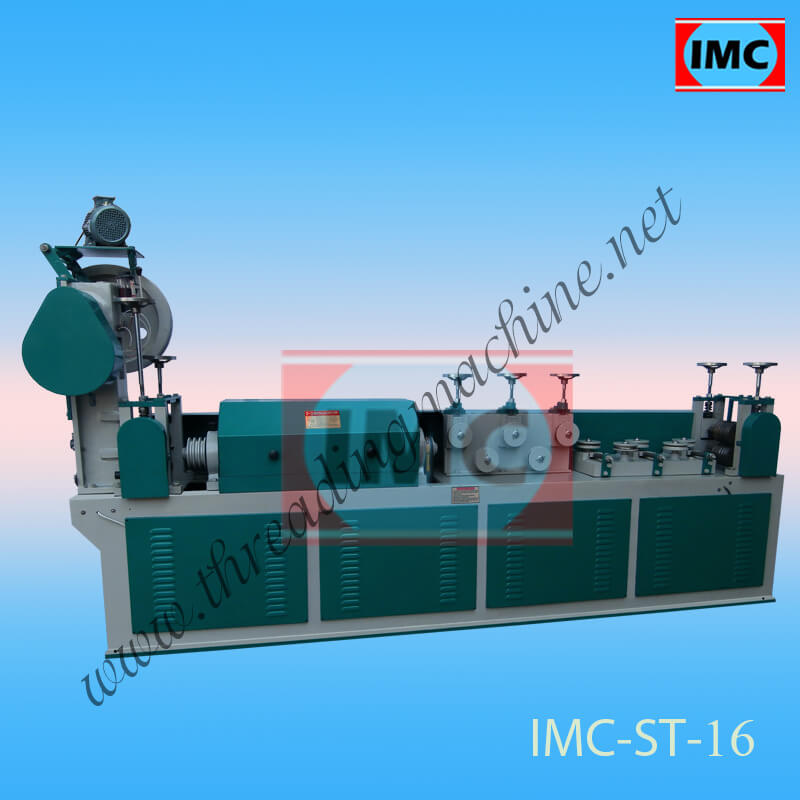

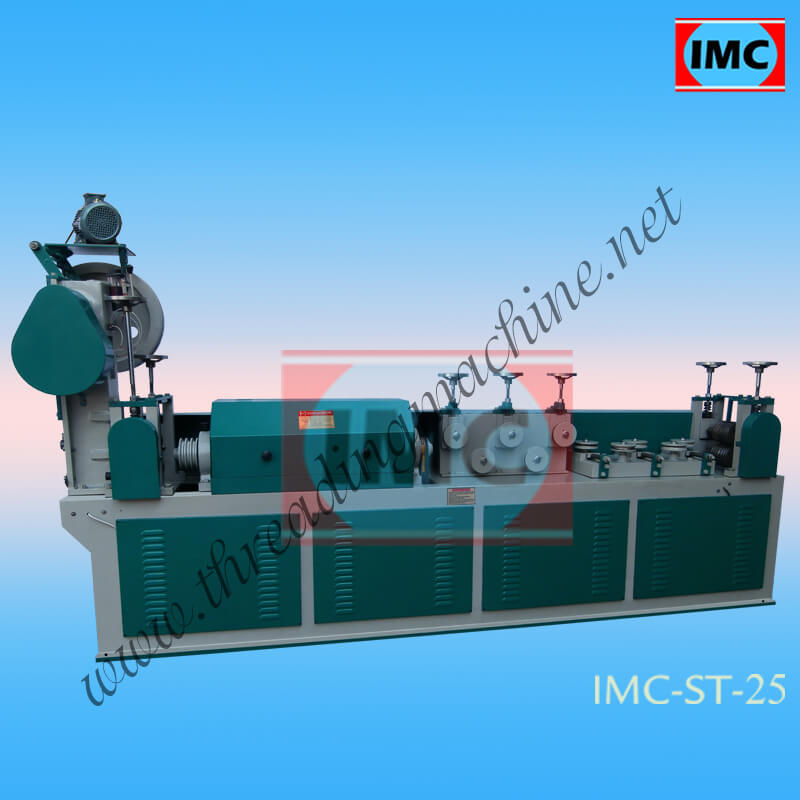

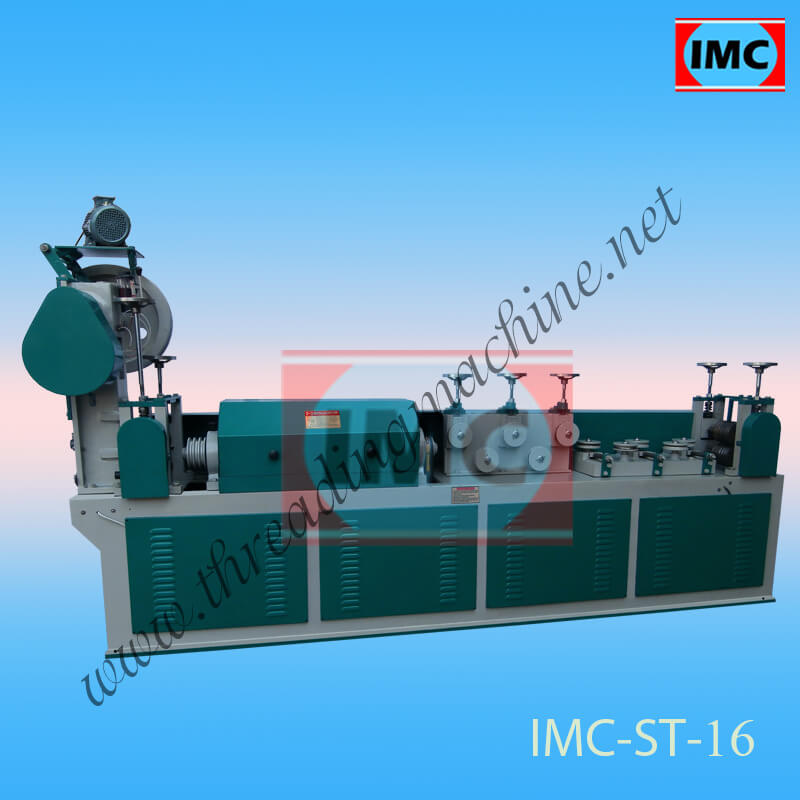

| Specifications : | IMC-ST-14 | IMC-ST-15 | IMC-ST-16 | IMC-ST-20 | IMC-ST-25 |

| In Thickness of wire | 5 to 14mm | 6 to 15mm | 8 to 16mm | 10 to 20mm | 15 to 25mm |

| In Length of wire to be cut automatically | As per Requirement | As per Requirement | As per Requirement | As per Requirement | As per Requirement |

| Feeding capacity per min. | 60' feet | 60' feet | 60' feet | 60' feet | 40' feet |

| Power of motor H.P. | 10 H.P. | 15 H.P. | 15 H.P. | 25 H.P. | 30 H.P. |

| Required R.P.M. | 1440 | 1440 | 1440 | 1440 | 1440 |

| Approx. Weight in Kg. | 1300 | 1500 | 2500 | 3000 | 3500 |

| Floor space required | 91"x22" | 105"x24" | 125"x24" | 150"x27" | 180"x36" |