Pipe Threading Machine

IMC (Industrial Machinery Corporation) is a well-known manufacturer and supplier of industrial machines, including pipe threading machines. IMC offers a range of pipe threading machines that are desig ...

VIEW MOREIndustrial Machinery Corporation (IMC) takes pride in offering well-designed Bar Thread Cutting Machines in India and abroad. With a strong focus on quality, innovation, and customer satisfaction, IMC has established itself as a reliable and reputable provider of industrial machinery.

IMC's Bar Thread Cutting Machines are meticulously engineered to meet the diverse needs of customers in various industries. Whether you're a small-scale workshop or a large manufacturing facility, IMC has the right solution to optimize your bar thread Cutting operations. Different types of threads can be cut on the bar such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads, etc.

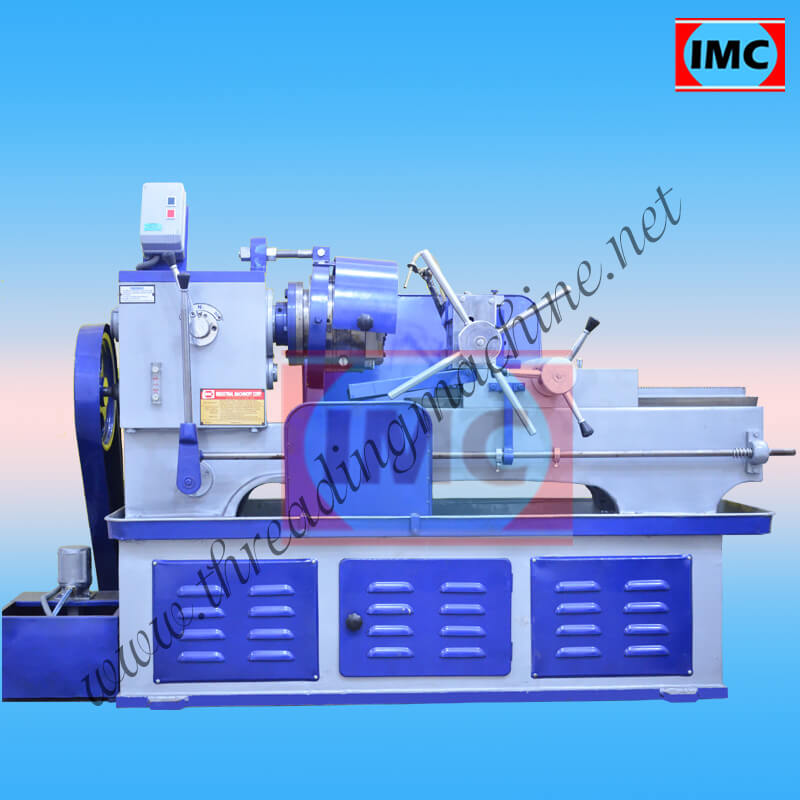

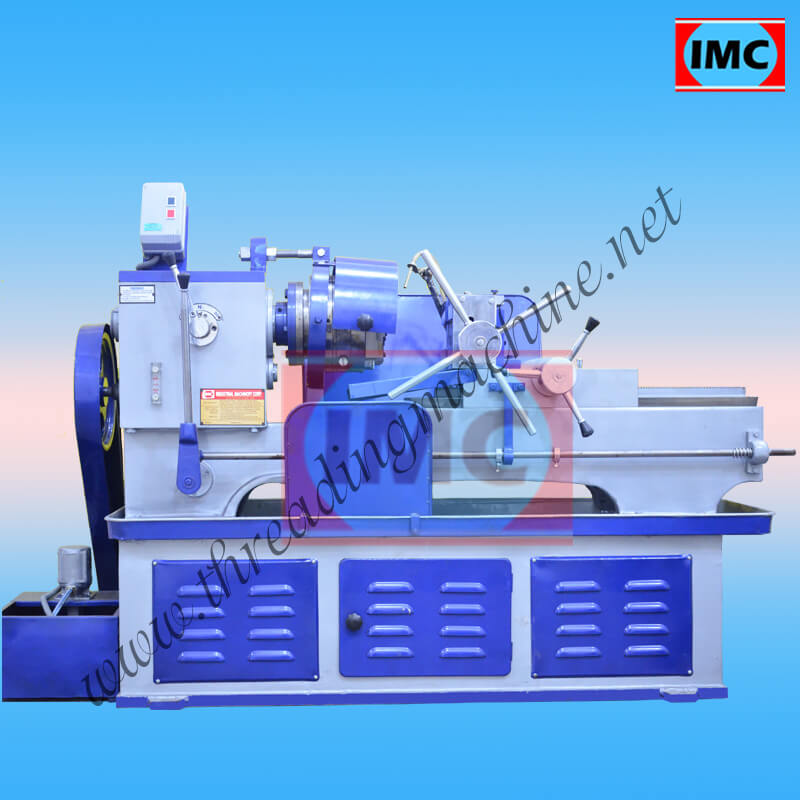

VIEW SPECIFICATIONSIntroducing the cutting-edge Bar Threading Machine, meticulously manufactured and supplied by IMC. As a leading manufacturer and supplier, IMC brings you a machine that redefines efficiency, precision, and reliability in the field of bar threader.

Built with precision engineering and advanced technology, this Bar Thread Cutting Machine sets new standards for thread Cutting operations. Designed to meet the demanding requirements of various industries, it delivers precise and consistent thread Cutting results on a wide range of bars, rods, and shafts, ensuring superior quality and performance.

Key Specifications:

Thread Cutting Capacity: The Bar Thread Cutting Machine offers an impressive thread Cutting capacity, accommodating bars of various diameters and lengths. From small-diameter rods to large-sized shafts, this machine tackles thread cutting tasks with remarkable ease and accuracy.

Thread Types: Versatility is at the core of this machine. It supports a wide range of thread types, including metric, inch, and custom threads. Whether you need standard thread Cutting patterns or specialized designs, this machine delivers flawless results every time.

Threading Speed: The Thread Cutting Machine features adjustable thread cutting speeds to suit different materials and thread specifications. Its high-speed operation ensures rapid production while maintaining precision and quality.

Cutting Mechanism: Equipped with advanced cutting mechanisms, this machine delivers clean and precise thread cuts. The cutting tools are designed to withstand the rigors of heavy-duty production, ensuring longevity and consistent performance.

Control Panel: The machine's intuitive control panel offers user-friendly operation and allows for easy adjustments. It provides quick access to thread cutting parameters, enabling operators to customize settings based on specific requirements, ensuring optimal performance.

Safety Features: IMC prioritizes operator safety. The Bar Threader is equipped with comprehensive safety features, including emergency stop buttons, protective enclosures, and sensors that prevent unauthorized access during operation. These safety measures provide peace of mind and ensure a secure working environment.

IMC's unwavering commitment to quality and reliability is evident in every aspect of the Thread Cutting Machines. Each component is meticulously crafted from premium materials and undergoes rigorous testing to meet international quality standards. This machine is built to withstand the demands of continuous and heavy-duty use, providing exceptional durability and reliability.

As a trusted manufacturer and supplier, IMC has a proven track record of delivering superior machinery. Our Bar Thread Cutting Machines have earned acclaim for their robust construction, advanced technology, and unmatched customer satisfaction. By choosing IMC as your supplier, you gain access to comprehensive support from our dedicated team of experts.

From installation and training to ongoing maintenance and technical assistance, IMC ensures that you receive the utmost support throughout the lifecycle of your machine. With IMC as your partner, you can optimize your bar thread cutting operations, increase productivity, and gain a competitive edge in your industry.

Experience the precision and efficiency of the Bar Threader Machine from IMC, and witness a new level of excellence in bar thread cutting. Trust IMC's expertise and commitment to innovation to take your manufacturing capabilities to unprecedented heights. Choose IMC, your trusted partner in the industry, and unlock limitless possibilities for your business.

As a trusted manufacturer, IMC ensures that its Threader Machines are built with precision and attention to detail. The machines undergo rigorous quality control processes to meet and exceed international standards, ensuring superior performance, durability, and reliability.

IMC's commitment to customer satisfaction extends beyond the sale of their machines. The company offers comprehensive after-sales support, including installation assistance, training, maintenance services, and technical guidance. IMC's dedicated team of experts is readily available to address any inquiries or concerns, ensuring a smooth and hassle-free experience for customers.

With a strong presence in both domestic and international markets, IMC has earned a reputation for delivering high-quality Bar Thread Cutting Machines that meet the diverse needs of customers worldwide. Whether you're based in India or abroad, IMC is dedicated to providing reliable and efficient solutions for your bar thread cutting requirements.

Choose Industrial Machinery Corporation for well-designed Bar Threading Machines that offer precision, reliability, and exceptional performance. Trust IMC to elevate your bar threader operations and help you achieve optimal results.

Range of IMC Bar Thread Cutting Die-Head.

1/4" to 1" do/-

3/8" to 1.1/2" do/-

1/2" to 2.1/2" do/-

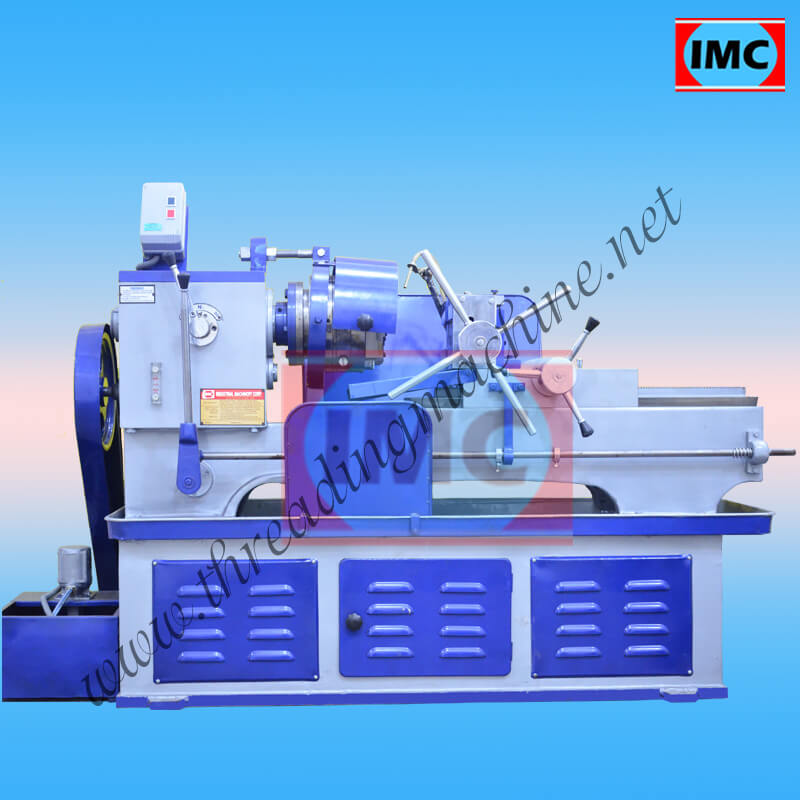

| MODEL | 1/4" TO 1" (6MM to 25MM) (BED TYPE) | 3/8" TO 1.1/2" (10MM to 40MM) (BED TYPE) | 1/2" TO 2.1/2" (12MM to 65MM) (BED TYPE) |

| Saddle Movement | 10" | 13" | 22" |

| Spindle Speed Range | 75-140 | 75 -140 | 45 - 90 |

| Number of Spindle Speed | 2 | 2 | 2 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

IMC (Industrial Machinery Corporation) is a well-known manufacturer and supplier of industrial machines, including pipe threading machines. IMC offers a range of pipe threading machines that are desig ...

VIEW MORE

Looking for a reliable Bolt Threading Machine? Look no further than IMC, a leading manufacturer and supplier of high-quality machinery. Our Bolt Thread Cutting Machines are designed to deliver excepti ...

VIEW MORE

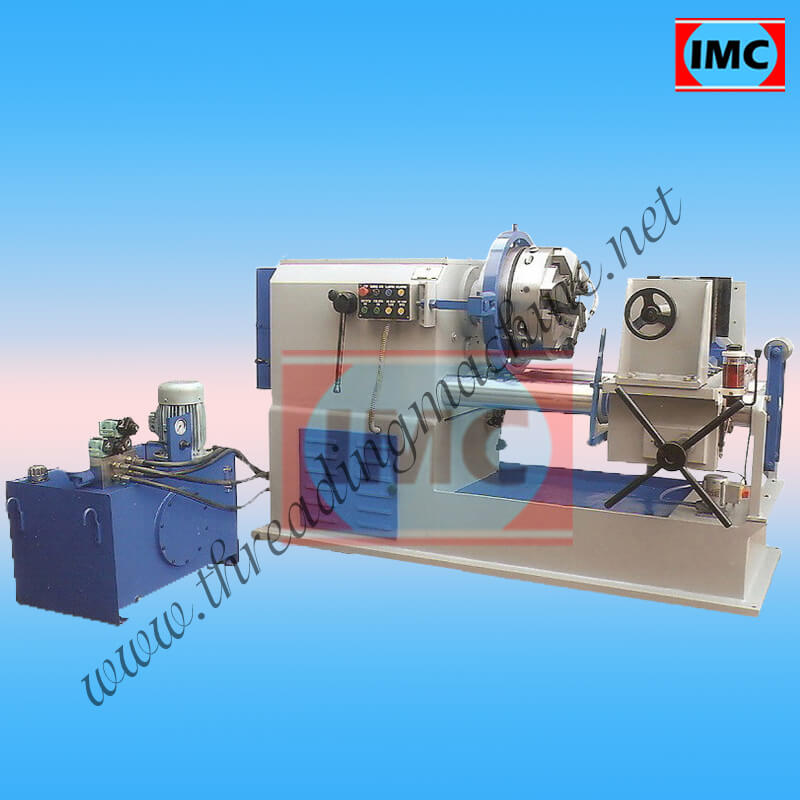

Industrial Machinery Corporation is proud to present our cutting-edge Hydraulic Pipe Threading Machine, designed to revolutionize your pipe threading processes. With its advanced features and exceptio ...

VIEW MORE

Rod Threading Machine is use to cut the external threads with the help of Tangential chaser. Chaser is use as a cutter in Machine. Job remain still, Die-head rotates and different type of threads can ...

VIEW MORE

We have a wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machine thre ...

VIEW MORE

Looking for a reliable and high-quality Electric Conduit Pipe Threading Machine? Look no further than Industrial Machinery Corporation (IMC), a trusted manufacturer, exporter, and supplier of top-of- ...

VIEW MORE