Pipe Threading Machine

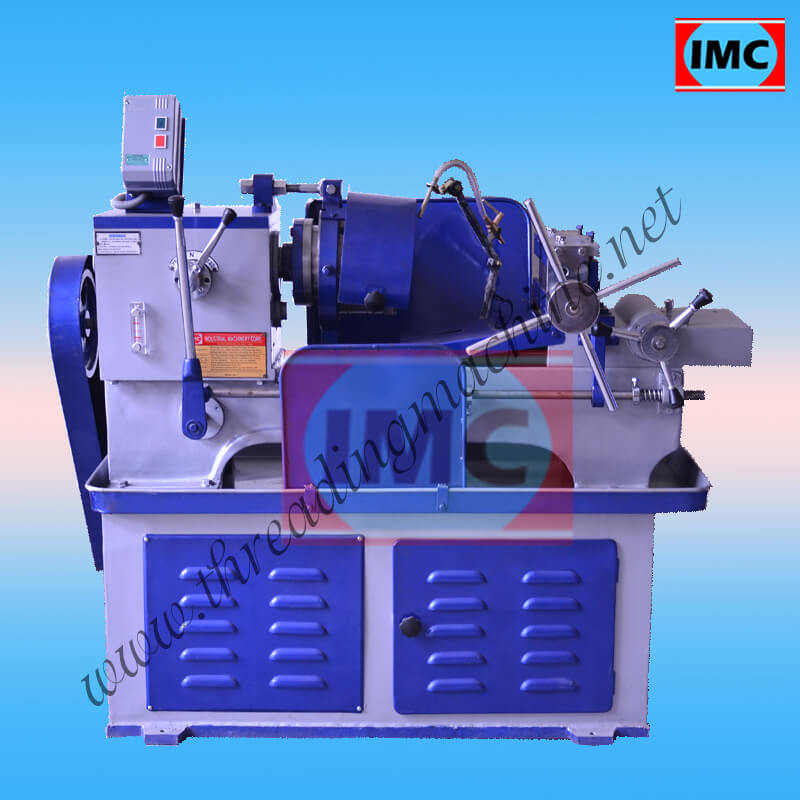

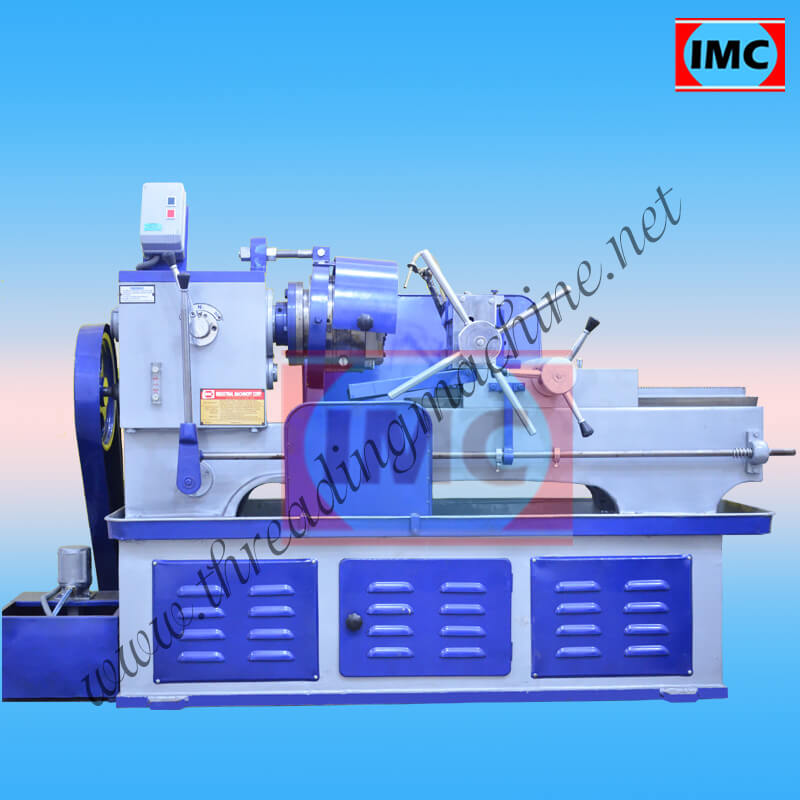

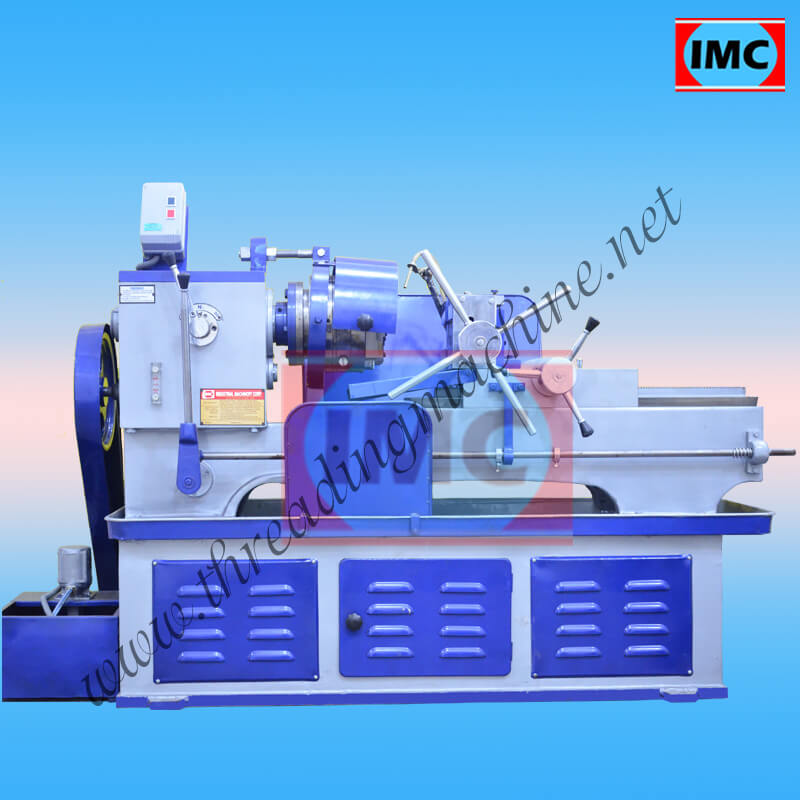

IMC (Industrial Machinery Corporation) is a well-known manufacturer and supplier of industrial machines, including pipe threading machines. IMC offers a range of pipe threading machines that are desig ...

VIEW MORELooking for a reliable and high-quality Electric Conduit Pipe Threading Machine? Look no further than Industrial Machinery Corporation (IMC), a trusted manufacturer, exporter, and supplier of top-of-the-line threading machinery. With extensive experience in the industry, IMC delivers exceptional Electric Conduit Pipe Threading Machines that meet the diverse needs of customers worldwide.

Looking for a reliable and high-quality Electric Conduit Pipe Threading Machine? Look no further than Industrial Machinery Corporation (IMC), a trusted manufacturer, exporter, and supplier of top-of-the-line threading machinery. With extensive experience in the industry, IMC delivers exceptional Electric Conduit Pipe Threading Machines that meet the diverse needs of customers worldwide.

Our Electric Conduit Pipe Threading Machine is designed with precision and innovation, offering unparalleled performance and efficiency in threading electrical conduit pipes. This machine streamlines the threading process, ensuring precise and reliable threading of pipes, and providing a reliable solution for your electrical installation projects.

Key Features of our Electric Conduit Pipe Threading Machine:

Advanced Threading Technology: IMC's Electric Conduit Pipe Threading Machine incorporates advanced threading technology to deliver precise and consistent thread formation. The machine utilizes efficient threading techniques, ensuring accurate and durable threads on electrical conduit pipes.

Versatility and Adaptability: Our Electric Conduit Pipe Threading Machine accommodates various pipe sizes and threading specifications. With adjustable settings and interchangeable dies, you can easily adapt the machine to meet your specific threading requirements, enhancing versatility and productivity.

High-Speed Threading: Equipped with a high-performance threading system, the machine provides rapid threading speeds, optimizing productivity and reducing threading cycle times. This enables you to meet project deadlines efficiently and effectively.

Robust Construction: IMC prioritizes durability and longevity in our threading machines. The Electric Conduit Pipe Threading Machine is built with high-quality materials and components, ensuring its ability to withstand continuous use in demanding industrial environments.

User-Friendly Interface: We design our machines with user convenience in mind. The Electric Conduit Pipe Threading Machine features an intuitive control panel and an ergonomic design, allowing for easy operation and quick adjustment of threading parameters. This promotes operator efficiency and minimizes downtime.

At IMC, we are committed to delivering exceptional products and ensuring customer satisfaction. Our Electric Conduit Pipe Threading Machines undergo rigorous quality control processes to meet international standards and exceed customer expectations.

As your trusted supplier, IMC provides comprehensive support throughout your purchase journey. From initial inquiries to after-sales service and technical assistance, our dedicated team of experts is here to assist you at every step.

Choose Industrial Machinery Corporation as your reliable partner for Electric Conduit Pipe Threading Machines. Experience the difference between our high-quality products, exceptional customer service, and industry expertise. Contact us now to explore our range of Electric Conduit Pipe Threading Machines and enhance your threading capabilities for electrical conduit pipe installations.

| MODEL | 1/4" TO 1" (6MM to 25MM) (BED TYPE) | 3/8" TO 1.1/2" (10MM to 40MM) (BED TYPE) | 1/2" TO 2.1/2" (12MM to 65MM) (BED TYPE) |

| Saddle Movement | 10" | 13" | 22" |

| Spindle Speed Range | 75-140 | 75 -140 | 45 - 90 |

| Number of Spindle Speed | 2 | 2 | 2 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

IMC (Industrial Machinery Corporation) is a well-known manufacturer and supplier of industrial machines, including pipe threading machines. IMC offers a range of pipe threading machines that are desig ...

VIEW MORE

Industrial Machinery Corporation (IMC) takes pride in offering well-designed Bar Thread Cutting Machines in India and abroad. With a strong focus on quality, innovation, and customer satisfaction, IMC ...

VIEW MORE

Looking for a reliable Bolt Threading Machine? Look no further than IMC, a leading manufacturer and supplier of high-quality machinery. Our Bolt Thread Cutting Machines are designed to deliver excepti ...

VIEW MORE

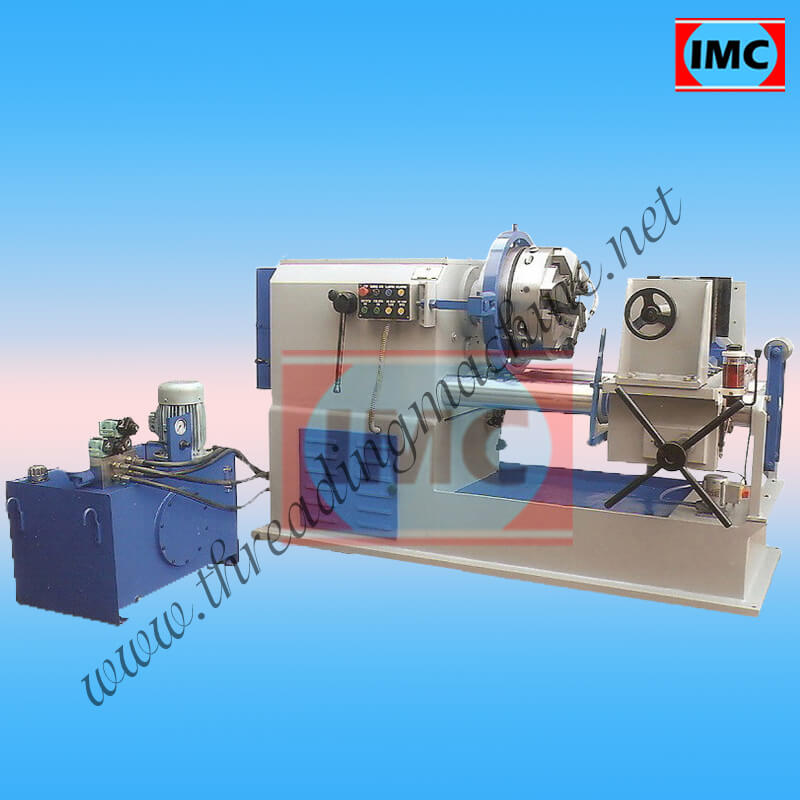

Industrial Machinery Corporation is proud to present our cutting-edge Hydraulic Pipe Threading Machine, designed to revolutionize your pipe threading processes. With its advanced features and exceptio ...

VIEW MORE

Rod Threading Machine is use to cut the external threads with the help of Tangential chaser. Chaser is use as a cutter in Machine. Job remain still, Die-head rotates and different type of threads can ...

VIEW MORE

We have a wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machine thre ...

VIEW MORE