Pipe Threading Machine

IMC (Industrial Machinery Corporation) is a well-known manufacturer and supplier of industrial machines, including pipe threading machines. IMC offers a range of pipe threading machines that are desig ...

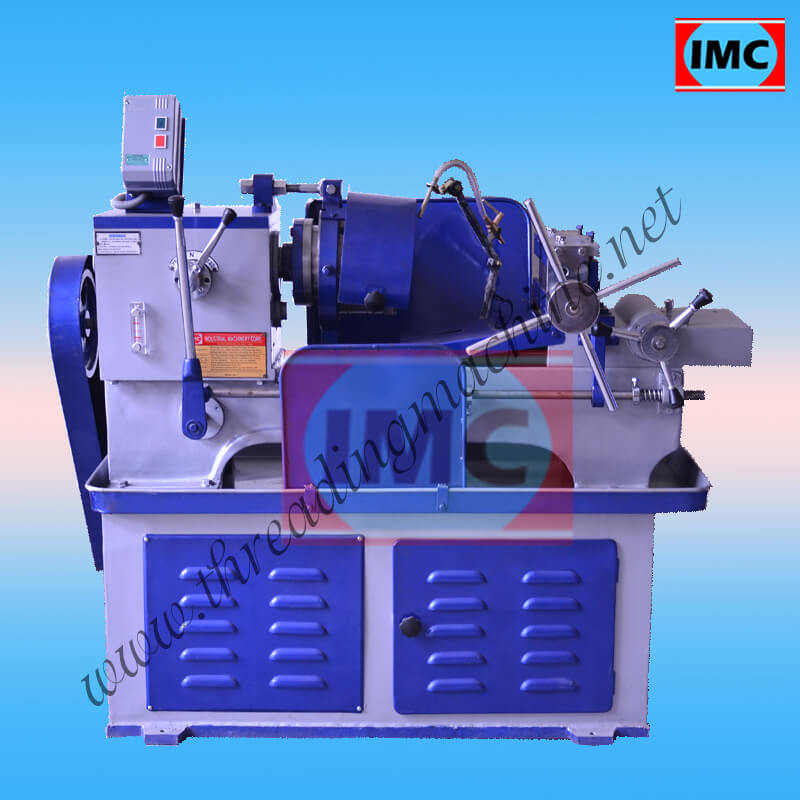

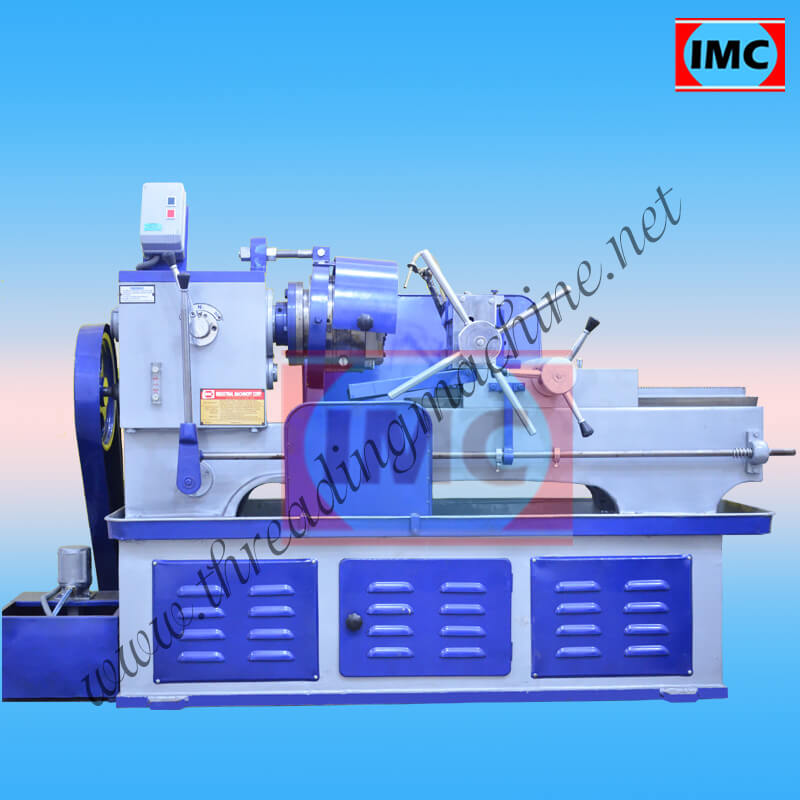

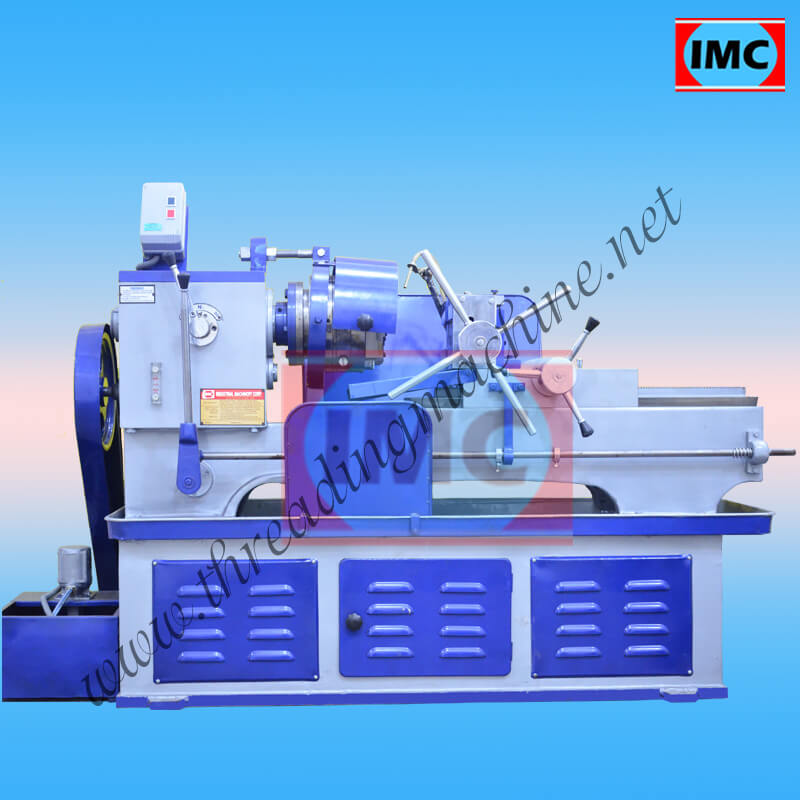

VIEW MOREWe have a wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machine threads the standard EN8-D TMT bar. The threading is done after the Rebar TMT bar forging process. Threading Machine is used for High Production. Industrial Machinery Corporation has been offering a High-Speed Steel TMT Chaser Rebar Threading Machine. This Rebar Threading Machine is made from high-density alloys. This machine is manufactured by our experts using excellent quality components and cutting-edge technology. This Threading Machine is used for saving time and effort. List of threads that can be cut using TMT Rebar Threading Machine: Matric, BSP, BSPT, NPT, UNF, UNC, BSW, Acme Threads, B.S.F. This Threading Machine has features like robust construction, high performance, and durability.

A Steel TMT Chaser Rebar Threading Machine is a specialized machine used for threading TMT (Thermo-Mechanically Treated) steel bars or rebars. These machines are commonly used in the construction industry for creating threaded connections in reinforced concrete structures.

Here are some key features and considerations when it comes to Steel TMT Chaser Rebar Threading Machines:

TMT Rebar Compatibility: These machines are specifically designed to work with TMT steel bars or rebars. TMT bars are commonly used for their superior strength and ductility in construction applications. The machine should be compatible with the diameter and grade of TMT rebars you intend to thread.

Chaser System: Steel TMT Chaser Rebar Threading Machines use chasers as cutting tools to create threads on the ends of the rebars. The chasers are typically made of high-speed steel (HSS) and have a specialized design to efficiently cut threads on TMT rebars.

Thread Types: These machines can create different types of threads, including both parallel and tapered threads. The specific thread standards supported by the machine may vary, so it's important to confirm compatibility with the required thread type.

Size Range: Steel TMT Chaser Rebar Threading Machines are available in different models to accommodate various sizes of TMT rebars. Ensure that the machine you choose can handle the specific rebar diameters and lengths you will be working with.

Power Source: These machines are typically powered by electric motors for efficient and consistent threading operations. Electrically powered machines offer faster threading speeds and precise control.

Clamping Mechanism: Steel TMT Chaser Rebar Threading Machines feature a clamping mechanism to securely hold the rebar in place during the threading process. The clamping mechanism ensures stability and prevents movement or rotation of the rebar, allowing for accurate threading.

Durability and Construction: Look for a Steel TMT Chaser Rebar Threading Machine that is built with high-quality materials and construction. These machines should be robust and able to withstand the demanding conditions of rebar threading operations in the construction industry.

It's important to note that specific features and specifications of Steel TMT Chaser Rebar Threading Machines may vary based on the manufacturer and model. For detailed information about specific machine models, including technical specifications, pricing, and availability, it's recommended to consult with manufacturers or suppliers specialized in rebar threading equipment.

When using a Steel TMT Chaser Rebar Threading Machine, it is essential to follow the manufacturer's instructions and safety guidelines for proper operation and maintenance. Adequate training and adherence to safety precautions are crucial to ensure the safe and efficient threading of TMT rebars.

| Model | 1/4" to 1" (6MM to 25MM) (Bed Type) | 3/8" to 1.1/2" (10MM to 40MM) (Bed Type) | 1/2" to 2.1/2" (12MM to 65MM) (Bed type) |

| Saddle Movement | 10" | 10" - 12" | 22" |

| Spindle Speed Range | 75-140 | 75-140 | 45-90 |

| Number of Spindle Speed | 2 | 2 | 3 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

IMC Tangential Threading Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standards. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended. These Tangential Chasers are used in Rebar Threading Machine.

IMC (Industrial Machinery Corporation) is a well-known manufacturer and supplier of industrial machines, including pipe threading machines. IMC offers a range of pipe threading machines that are desig ...

VIEW MORE

Industrial Machinery Corporation (IMC) takes pride in offering well-designed Bar Thread Cutting Machines in India and abroad. With a strong focus on quality, innovation, and customer satisfaction, IMC ...

VIEW MORE

Looking for a reliable Bolt Threading Machine? Look no further than IMC, a leading manufacturer and supplier of high-quality machinery. Our Bolt Thread Cutting Machines are designed to deliver excepti ...

VIEW MORE

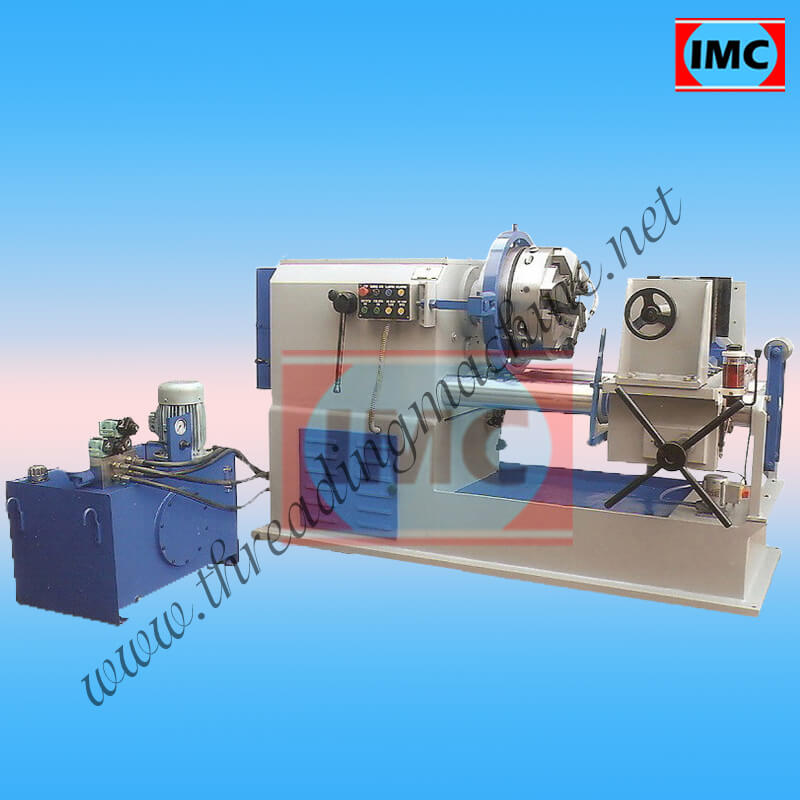

Industrial Machinery Corporation is proud to present our cutting-edge Hydraulic Pipe Threading Machine, designed to revolutionize your pipe threading processes. With its advanced features and exceptio ...

VIEW MORE

Rod Threading Machine is use to cut the external threads with the help of Tangential chaser. Chaser is use as a cutter in Machine. Job remain still, Die-head rotates and different type of threads can ...

VIEW MORE

Looking for a reliable and high-quality Electric Conduit Pipe Threading Machine? Look no further than Industrial Machinery Corporation (IMC), a trusted manufacturer, exporter, and supplier of top-of- ...

VIEW MORE